Nikon FM3A

- Manual-focusing SLR camera "Nikon FM3A" born in the 21st century

- Major Specifications of FM3A

- AI Nikkor 45 mm F2.8P and "FM3A" went on sale simultaneously, becoming a topic of considerable interest.

- Major Specifications of AI Nikkor 45mm F2.8P

- Receiving unexpected favorable reviews

- Implementation of a hybrid shutter

- Traditional style indications within finder

- Major difficulty of control section

- Sophisticated body and refined capabilities

- Debut of FM3A and the story of what happened later to the camera

Manual-focusing SLR camera "Nikon FM3A" born in the 21st century

Nikon FM3A is a manual-focusing SLR (single-lens reflex) film-based camera released in July 2001, offering aperture-priority auto and manual exposure controls.

Nikon's first SLR camera to incorporate an aperture-priority auto-exposure (AE) mode is Nikkormat (Nikomat in Japan) EL introduced in 1972. The aperture-priority auto-exposure (AE) mode allows the user to easily obtain the correct exposure by selecting a desired aperture, since the camera automatically determines the optimum shutter speed for the selected aperture. This mode was incorporated in Nikon F3, FE and other various models. It was the most common automatic exposure control system before the emergence of the programmed auto-exposure in the 1980s, which automatically selects an optimum combination of aperture and shutter speed.

Cameras have been equipped with automatic functions primarily by adopting electrical controls to take on the operations and settings in place of the users. In order to implement the automatic exposure control, cameras have been equipped with electronic circuits for electronic control of shutter speeds in synchronization with metering system and exposure meter. Then, in the cameras with the aperture-priority AE mode, the timing of shutter operation was controlled by an electronic timer in most models even in the manual exposure mode, in which any desired shutter speed may be selected at the users' discretion.

On the other hand, before the electronically controlled automatic exposure (AE) control became available, users used to manually select the appropriate aperture and shutter speed combination to take photographs by referring to the readings on the exposure meter and/or based on their experience. It was exactly a manual exposure mode. Nikon's SLR cameras were based on the manual exposure except some models until the Nikkormat EL was introduced. In response to the user's selection of shutter speed, the timing of shutter operation was set on the mechanically operated governor. The governor required some energy to operate, though the operation of a lever for film advancing acted as clockwork to charge the energy to the governor, obviating the need for a battery. In those days, when batteries were hard to obtain unlike recent years, or in frigid regions where batteries do not work, the manual exposure control cameras came in very handy.

Many users were demanding both features, the convenience of aperture-priority AE and the reliability of mechanically controlled shutter operation without any battery (some models with an electronically controlled shutter were designed to allow mechanical shutter control at only one speed such as 1/90 sec. for emergency use in the event of battery depletion).

The FM3A successfully implemented both features in conjunction. It was equipped with a shutter to allowed electronic control in the aperture-priority AE mode, and a mechanical control in the manual exposure mode. Because it adopted both control systems, electronic and mechanical, the shutter was called hybrid shutter. It was the first shutter system for Nikon and was also a very valuable system around the world.

The FM3A was also equipped with TTL (through-the-lens) flash control of Speedlight, automatic setting of film sensitivity and other features in addition to the exposure meter with an indicator needle which had an established reputation among the users.

The FM3A was placed on the market in July 2001 at 96,000 yen (tax not included) for the silver finish body and 99,000 yen (tax not included) for the black finish body.

Major Specifications of FM3A

| Type of camera | Electronically-controlled and mechanically-controlled 35 mm single-lens reflex (SLR) focal-plane shutter camera |

|---|---|

| Film format | 35 mm (135) format |

| Exposure control | Aperture-priority auto (A) and manual (M) exposure control |

| Picture size | 24×36 mm |

| Lens mount | Nikon F mount |

| Viewfinder | Eye-level pentaprism type |

| Eye point | 14 mm at -1.0 -1(dpt.) |

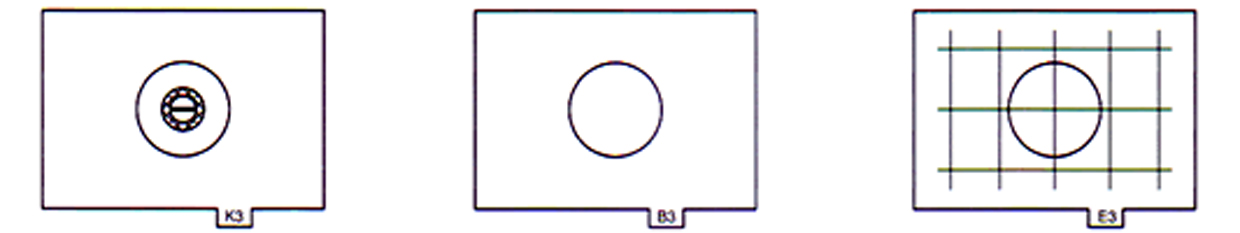

| Focusing screen | K3 type (splitprism-image microprism type, Cear matte Screen II) standard, B3 type and E3 type optional |

| Finder coverage | Approx. 93% (objective screen) |

| Magnification of finder | Approx. 0.83X (with 50 mm set to infinity) |

| Viewfinder information | Shutter speed, exposure meter indication, shutter indication, direct aperture value, exposure compensation mark, ready light |

| Reflex mirror | Quick-return type |

| Metering system | TTL center-weighted, full-aperture exposure metering system, approx. 60% of the meter's sensitivity concentrated on a 12 mm diameter circle |

| Exposure meter sync. | AI type |

| Metering range | EV 1 to 20 (ISO 100) (with use of 50 mm f/1.4 lens) |

| Film-sensitivity setting | DX system or manual. With DX: ISO25 to 5000 Manual: ISO 12 to 6400 |

| Exposure compensation | Exposure compensated to ±2EV in units of 1/3 |

| AE lock | Enabled by pressing the AE lock button |

| Shutter | Vertical-travel metal focal-plane shutter |

| Shutter speed settings | A (Aperture-priority auto): 8 to 1/4000 s. electronic stepless control (indications are 1 to 1/4000) M (Manual): Bulb,1 to 1/4000 s. mechanical control |

| Self-timer | Mechanically controlled, countdown time of approx. 4 to 10 seconds, cancellation possible |

| Lens aperture | Instant-return system, with aperture lever |

| Sync contact | X-contact only; synchronized with the flash at a low speed of less than 1/250s |

| Speedlight control | TTL flash |

| Sync. terminal | JIS sync terminal provided as standard, with lock screws |

| Flash ready light | Lights up when SB-27, SB-28 and others have been fully charged; Blinks to warn of insufficient light output, and shutter speed setting at 1/500 to 1/4000 sec. |

| Accessory shoe | Standard ISO518-compliant shoe: Provided with flash sync. contact, ready-light signal contact, monitor signal contact, TTL auto flash stop signal contact, and safety lock hole |

| Film advance | Lever provided, 30-degree standoff angle and 135-degree winding angle, automatic film advance enabled with MD-12 motor Drive (Sold separately) |

| Frame counter | Aditive type (S, 1 to 36), automatic reset |

| Film rewinding | film reset button and rewind crank provided |

| Camera back | Detachable hinged back; MF-16 Data Back can be attached in place. |

| Camera back opening | Achieved with the film-rewind lever |

| Multiple exposure | Activated with multiple exposure lever |

| Power source | Choice of one (1) 3V CR-1/3N lithium battery, two (2) 1.55V One 3V CR1/3N lithium battery, two 1.55V SR44 silver-oxide batteries, or two 1.5V LR44 alkaline batteries |

| Meter-on timer | ON when the shutter button is half-pressed and automatically OFF 16 seconds after the shutter button is released. ON when the shutter button is half-pressed and automatically OFF approx. 66 seconds after the shutter button is released when the motor drive unit MD-12 is used. |

| Battery power check | Displayed for 16 seconds with the meter-on timer. The exposure meter does not work if the batteries are exhausted. |

| Total number of film rolls (in the aperture-priority AE mode) | Approx. 100 <Approx. 50> with use of 3V CR-1/3N lithium battery Approx. 100 <Approx. 50> with use of 1.55V SR44 silver oxide batteries Approx. 45 <Approx. 10> with use of 1.5V LR44 alkaline batteries *At ordinary temperature (20°C): The values in <> refer to the numbers at a low temperature (-10°C). The above listed values assume the use of 36-exposure film, aperture-priority AE mode and shutter speed of 1/250 sec. Measurement was conducted by repeating a cycle composed of half-pressing of 10-second duration followed by releasing and then leaving the shutter until the half-press timer expired. |

| Tripod socket | 1/4 (ISO 1222) |

| Dimensions & Weight (Approx.) | 142.5 (W) ×90 (H) ×58 (D) mm, 570 g (including batteries) |

AI Nikkor 45 mm f/2.8P and "FM3A" went on sale simultaneously, becoming a topic of considerable interest.

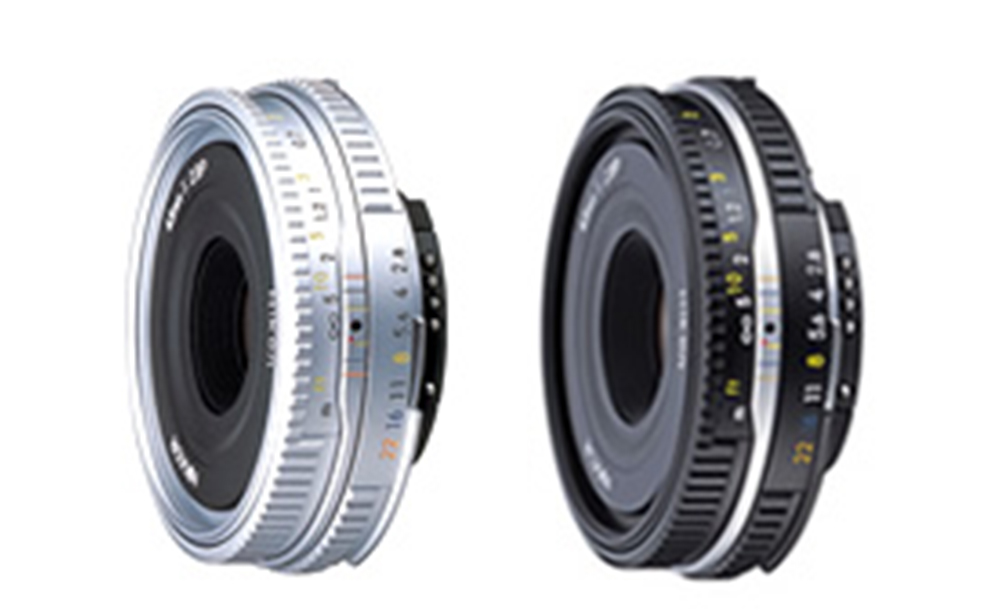

In July 2001, the single focal-length manual-focusing lens went on sale simultaneously with FM3A. It features a thin and lightweight design with a distance of 17 mm from the mount surface, and a weight of approx. 120 g. It is commonly called pancake lens for the external view. Due to the newly designed Tessar-type optical system (configuration of 4 elements in 3 groups) and the 7-blade circular diaphragm, it provides excellent imaging characteristics. In consideration of the proper matching to the FM3A, it was finished with a quality metallic appearance. The filter, hood, and cap were also designed specifically for this lens system, and particularly the hood was equipped with a specific function to allow installing a cap over the hood and a novel conical-dome design. A CPU was integrated in the system to allow all exposure control modes, programmed, aperture-priority, shutter-speed priority, and manual. In addition to the silver finish, the black finish system was released in November 2001 at 48,000 yen (tax not included).

Major Specifications of AI Nikkor 45mm f/2.8P

| Type of lens | Nikon F mount CPU-integrated P type manual focus lens |

|---|---|

| Focal length | 45 mm |

| Max. aperture ratio | 1:2.8 |

| Lens configuration | 4 elements in 3 groups |

| Angle of view | 50°when mounted on 35 mm (135) format camera: 41°50' when mounted on an IX240 format camera: 34°50' when mounted on a Nikon digital camera D1 series |

| Object distance information | Unavailable output of object distance information into the camera body |

| Focus adjustment | Rotating system with range ring |

| Shortest object distance | 0.45 m |

| Aperture control | Automatic aperture control |

| Diaphragm | 7 blades (circular diaphragm) |

| Attachment size | 52 mm |

| Dimensions & Weight (Approx.) | 63 (Max. diameter) ×17 mm (Length: measured from the bayonet reference surface to the tip of the lens), 120 g |

| Accessories | Dedicated 52 mm spring-loaded front cap, dedicated rear cap (camera back), dedicated 52 mm NC filter, dedicated hood HN-35, and dedicated soft case |

Receiving unexpected favorable reviews

Market debut

Nikon FM3A went on sale in July 2001. At that time, digitization was proceeding in full swing. The camera industry was no exception and Nikon released the digital SLR camera D1 in 1999 for professional use. In 2001, Nikon put the D1X and D1H on the market in May and July, respectively. Just at the time when digital cameras were going to the mainstream, Nikon made the conscious choice of placing the FM3A on the market as a manual SLR camera.

In those days, some users were moving over to digital cameras while others were using auto-focus SLR cameras. In addition, there were those who loved the traditional manual Nikkor lenses. It was a period of transition to digital cameras and diversified needs crossed with each other. Can you imagine selecting the appropriate exposure manually and adjusting the lens focus each time you take a photograph? In this camera, Nikon should have placed a message about going back to the basics of camera and photography.

The camera was initially scheduled to go on sale in April 2001, but it was released in July, three months behind schedule. The delayed date of sale was forced by the rush of orders for the product after the announcement of introduction and the failure to secure an adequate supply due to a great deal of manual operations involved for assembly and adjustment.

Development team by selecting the finest staff

The development of FM3A was launched in December 1998. Unlike the conventional approaches for product development, the engineering staff from Mito Nikon, an group company, joined the engineers in the Ohi Plant from the very beginning of development to form a project team. Mito Nikon had been primarily involved in the manufacturing of the Nikkormat series and other mechanical cameras. The Mito Nikon staff, assigned to mass production, joined the development team from the start in order to prepare for many required manual operations for assembly and adjustment in the fabrication process and ensure a high level of quality control throughout the entire process, from development to mass production.

The team was first formed with seven members. Though later was increased to twelve, the select few worked for development in a room in the Ohi Plant.

Implementation of a hybrid shutter

Successful combination of aperture-priority AE and battery-free operation

Around April of 1999, when a rough product concept of FM3A was established after about four months of discussion, the project went into full swing.

The manual exposure and mechanically controlled New FM2 had long been a best-seller since its first introduction in 1984, enjoying a persistent popularity. It was favorably used by experienced amateur photographers, students of photography fundamentals, and other users deeply interested in the operations and processes for taking photographs. In addition, it offered the major benefit of shooting being possible even when the battery was exhausted. On the other hand, however, there was an increasing demand to provide the New FM2 with the aperture-priority AE and automatic flash control of Speedlight.

The project team studied over and over how to meet the demand. Eventually, in order to address the primary concern of users, that is, the simultaneous availability of aperture-priority AE and battery-free shutter operation, the project team decided to adopt the mechanism called hybrid shutter.

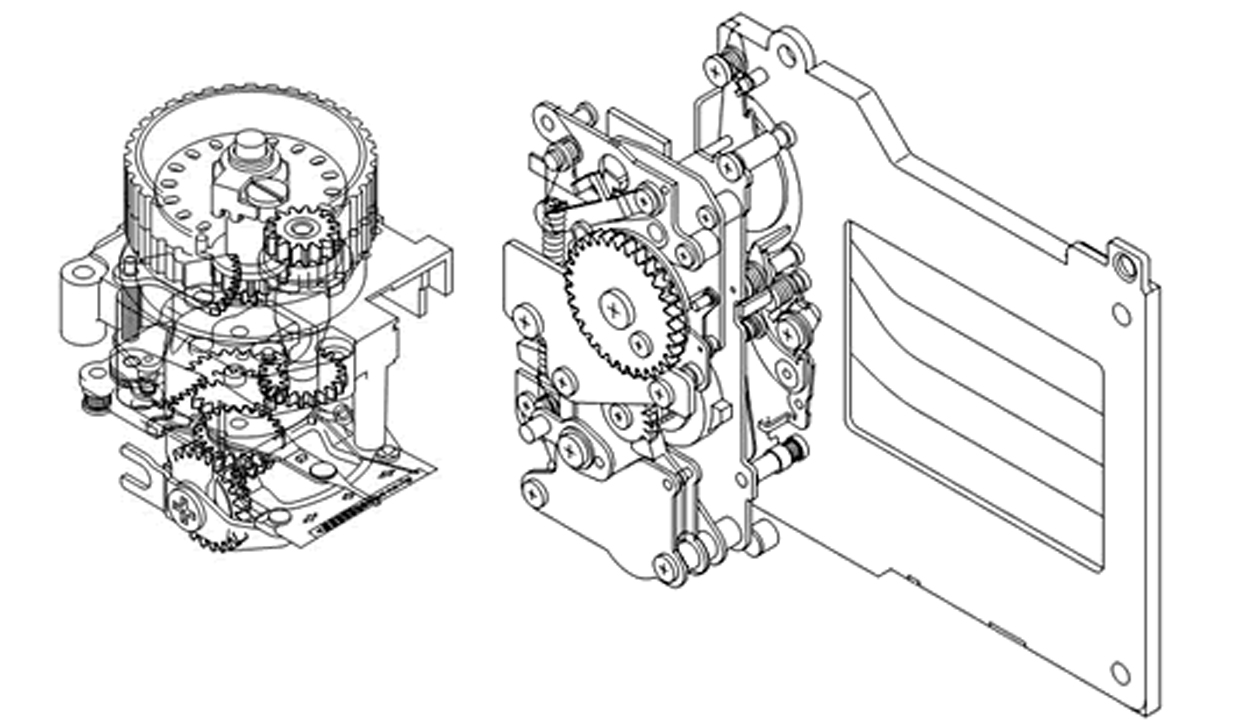

Hybrid shutter

The hybrid shutter electronically controls the shutter in the aperture-priority AE mode, while it provides mechanical control of the shutter in the manual exposure mode. This means the shutter can be operated in the manual exposure mode even without a battery.

This design means that one shutter must properly operate with two control systems, resulting in a complicated shutter mechanism. Furthermore, the number of required component parts and also the size of the shutter unit had to be increased accordingly. To install the shutter unit, it was essential to increase the space for mounting. In practice, however, since the FM3A was considered as a successor to the New FM2, the upsizing of the camera was not permitted. A method for mounting the unit in a limited space had to be devised.

In addition, the fabrication of shutter units had been assigned to subcontractors, although the development of the shutter unit operating on special mechanical and electrical combined designs was limited to some experienced expert engineers. The experienced engineers repeatedly offered advice to younger engineers.

In general, it is difficult to ensure the accuracy of mechanical shutters as they are designed to offer higher operating speeds. In addition, it was extremely difficult to develop a shutter unit with a complicated mechanism for hybrid operation, and in the early stages, it was thought that the highest speed of 1/4000 second would be impossible to realize. However, finally, after careful adjustment, the demanding criteria were successfully cleared.

Traditional style indications within finder

Intuitively easy-to-understand exposure meter with indicator needle

(showing a montage photograph)

The hybrid shutter was an innovation for the FM3A. On the other hand, FM3A adopted the traditional exposure meter with indicator needle, which had been continuously applied from the Nikkormat EL released in 1972. Looking at the viewfinder, several pieces of exposure-related information are indicated on the left side of the screen. For the analog meter, a rough estimate of needle position helps to intuitively understand the shutter speed in the aperture-priority AE mode. Thus this model was highly regarded especially by experienced users.

The meter with needle indicator is an ultra-compact ammeter similar to those used in level meters for audio equipment. However, there was no Japanese manufacturer in those days that could fabricate an ammeter that was small enough to install in the camera and satisfy the specified precision. The request for fabrication was rejected because, "We are not competent to fabricate such a small and high-precision product." After a long search, a manufacturer specializing in the production of ammeters was discovered in a foreign country. However, satisfactory accuracy was not achieved, then, after repeated consultations with the on-site engineers, and with patience, finally a satisfactory level of product accuracy was attained.

A used FE2 was procured from a second-hand camera shop and it was dismantled and the ammeter was removed. It was found that the compact-sized and high-precision ammeter that Nikon was seeking to design was built largely based on hand work. The real ammeter removed from FE2 was shown to the engineers in the subcontractor and specific instructions were repeatedly provided.

Enhanced visibility of shutter speed indication

The indication of exposure-related information within the viewfinder was based on Nikon's longstanding practices, though the visibility of information was enhanced due to improvements. The enhancements would be clearly understood by comparison, though the numeric characters vertically arranged to show that the shutter speeds are considerably larger compared to those adopted in FE2. The size of the numeric characters was increased to improve the visibility for experienced elderly users. However, that caused the misalignment between the needle on the shutter (blue frame showing the selected shutter speed) and the numeric characters to be more conspicuous. Smaller size numeric characters are easy to fit in the blue frame, though larger numerical characters are not. Then, improvements were made including a wider blue frame, and adjustment by manual operation was added in the fabrication process.

In addition, special consideration was given to ensuring the smooth motion of the pointer on the ammeter without any interference from static electricity, and a balancer was incorporated to keep the pointer in balance without any effect even if the ammeter becomes slanted due to the tilted camera.

Major difficulty of control section

Hybrid-compatible control section

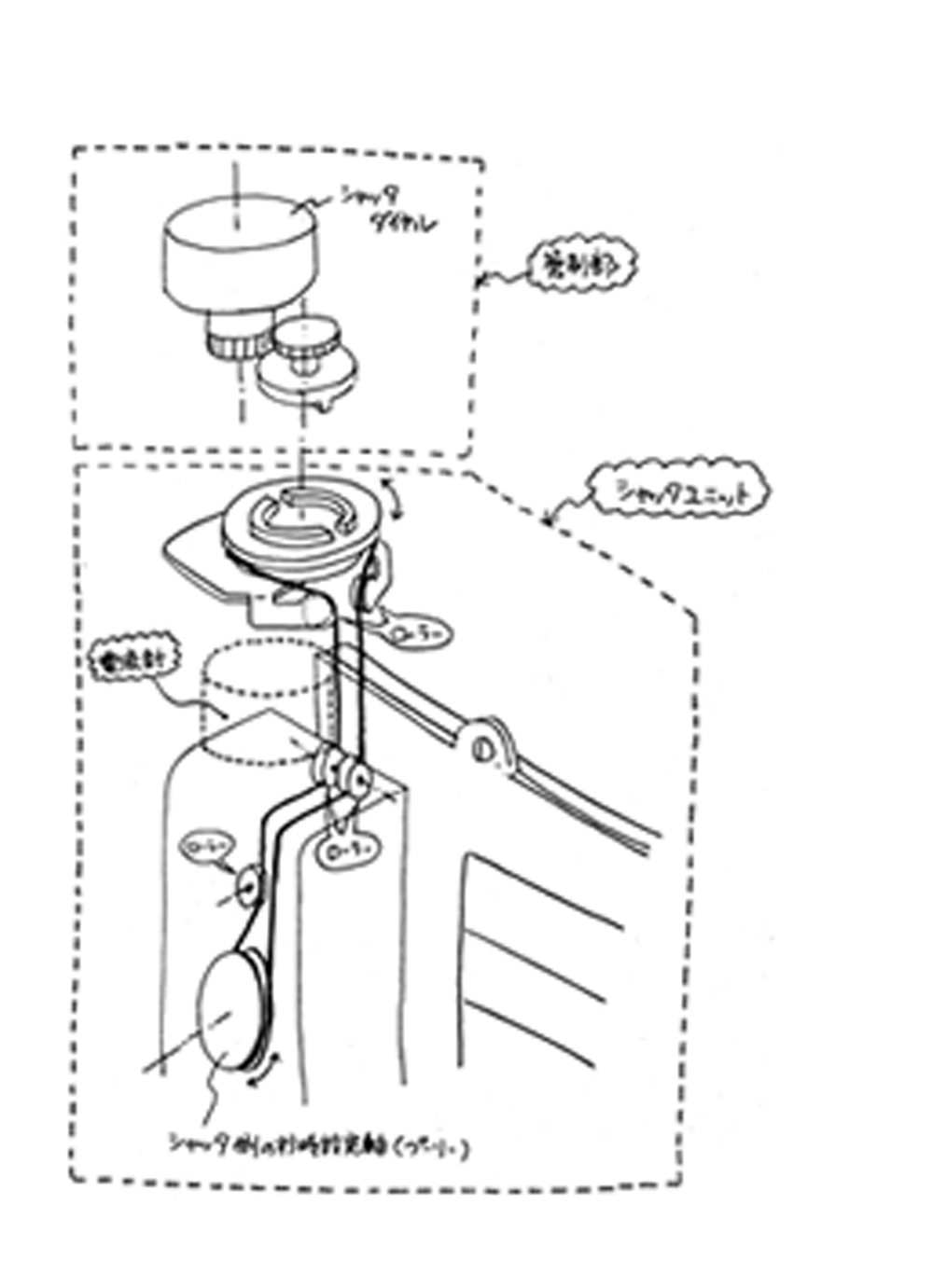

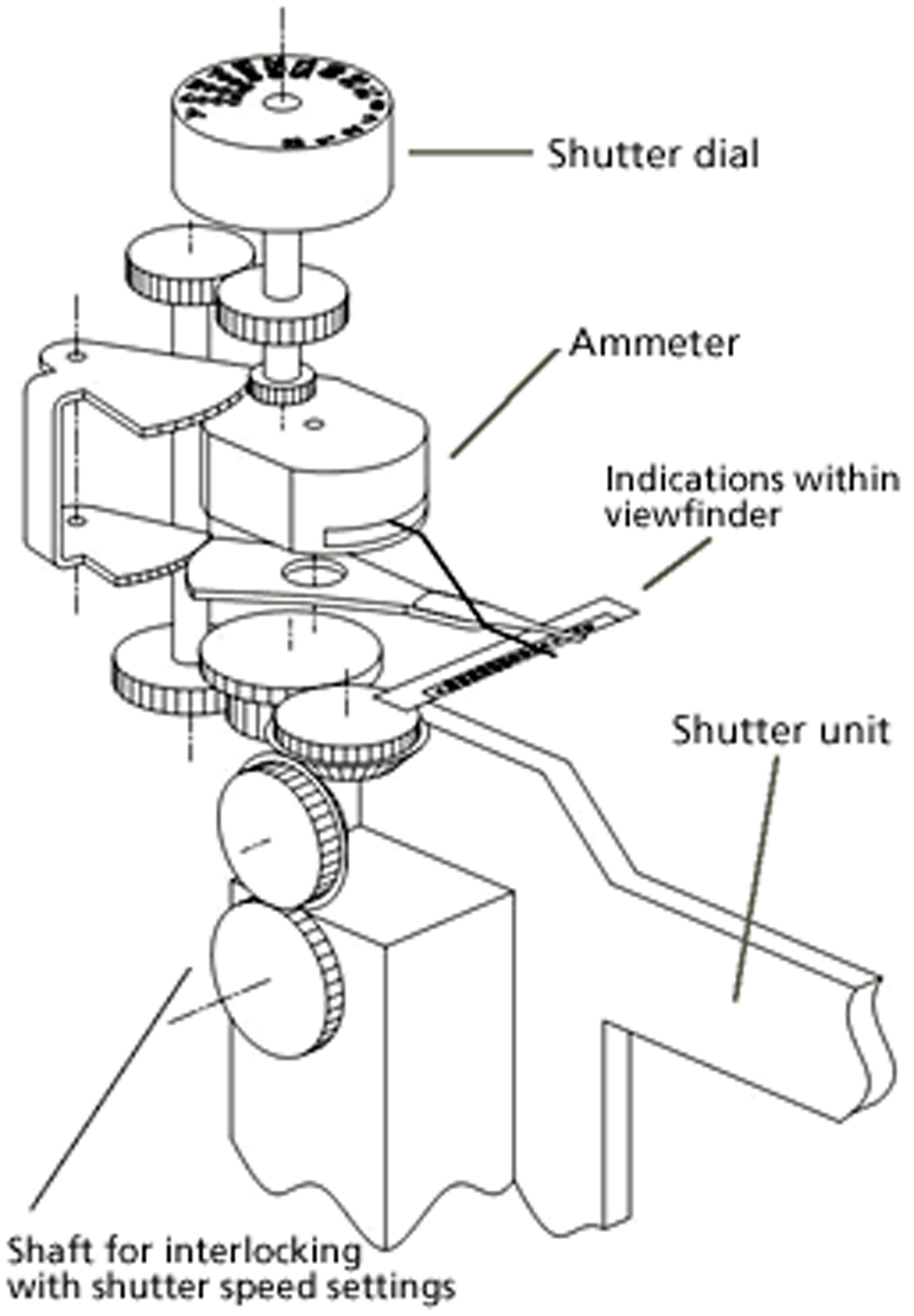

The shutter dial in the FM3A has the numeric characters of a series of multiple numbers from 1 through to 1000, 2000 and 4000 and the alphabet letters A and B inscribed. When the individual characters are aligned with the indicator, the shutter is set at aperture-priority AE for A, 1/4000 sec. for 4000, one second for 1, and bulb for B (shutter kept at full open), respectively. The mechanism to transmit the shutter dial settings to the shutter unit was called control section.

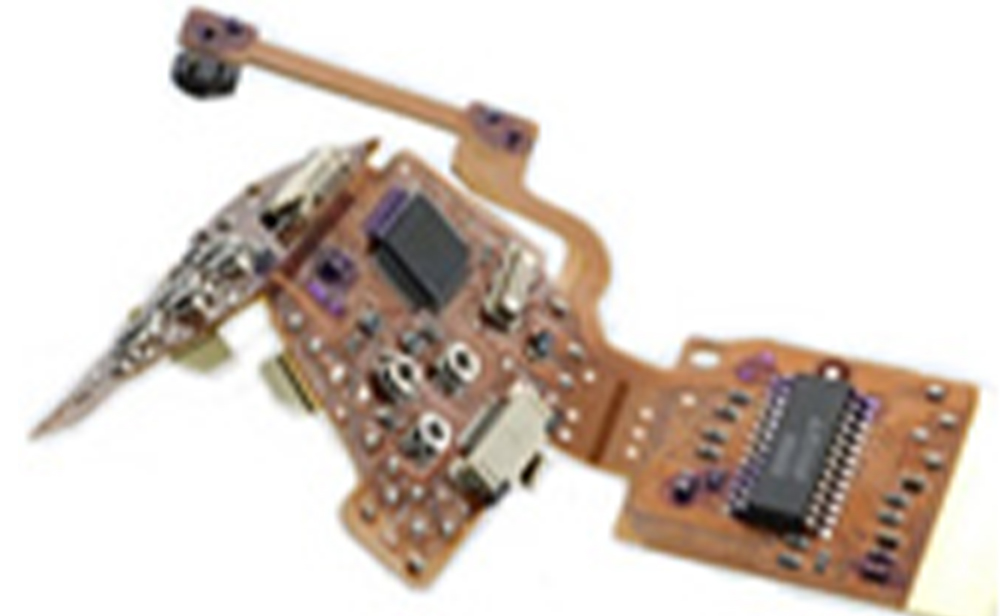

The control sections for FM3A, FM2 and FE2 are shown below. The control section for FM3A is much more complicated. The control section for FE2 is the simplest, and in terms of mechanical operation, it activates the needle within the viewfinder and electrically controls the shutter. The control section for FM2 is designed to provide mechanical linkage between the shutter dial and the shutter unit, and the linkage is configured with three gears. The control section for FM3A incorporates the mechanism of both control sections for FE2 and FM2 for the hybrid shutter.

Switching between electronic control and mechanical control

The shutter unit had to be provided with a mechanism to allow switching between electronic control and mechanical control in response to shutter dial settings such as aperture-priority AE and 1/4000 sec. in the manual exposure, transmitted to the shutter unit from the control section.

A focal-plane shutter is composed of front curtain and rear curtain. The time difference from the start of traveling of front curtain to the start of traveling of rear curtain corresponds to exposure time. In the FM3A, in the aperture-priority AE mode, electronic control becomes active, and when the timer expires the predetermined time setting, the rear curtain stop shoe is released and the rear curtain travels, completing the exposure. In the manual exposure, the mechanical governor instead of the timer reaches a predetermined time, the rear curtain stop shoe is removed and the rear curtain travels.

Typical shutter units contain a single rear curtain stop shoe, though the hybrid shutter in FM3A has two shoes for electronic control and mechanical control for proper use based on the settings on the control section. In practice, in the manual exposure mode other than A mode, the shoe for electronic control is retracted and the mechanical control becomes active, while in the aperture-priority AE mode available by selection of A, the shoe for electronic control pops out for activation.

The operational principle may seem simple when described, but it was hard work to mount the complicated mechanism in a confined area, and a part of camera body was depressed as a desperate measure.

Bypassing the ammeter

In the FM3A, the shutter becomes mechanically controlled in the manual exposure mode and the entire shutter unit is also set under the mechanical control of control section.

From the simple external view of camera, it may be postulated that a shaft is located directly below the shutter dial and it extends to the shutter unit to allow direct transmission of shutter speed settings. In practice, however, extremely complicated mechanical linkages were required. As the ammeter lies just in the middle between shutter dial and shutter unit, the mechanical linkages must be configured getting around the ammeter to ensure the interlocking between shutter dial and shutter unit. The FM2 does not contain any ammeter, therefore there is adequate space. The FE2 contains an ammeter in a similar position, though the interlocking is achievable simply by electrical wiring. However, the FM3A had to incorporate the mechanisms of both FM2 and FE2 in the same area of space.

In the initial design, there was no space left below the ammeter, and an attempt was made to install a wire for interlocking. The interlocking through wire was once adopted in the FM. In actuality, when a wire is installed as threading the way through several rollers to change the direction in a confined area, the wire is too long and as a result, due to the slack or looseness in wire caused by its extended length, smooth clicking and interlocking could not be obtained.

There was no choice other than gear-combined linkages. Radical reassessment was made regarding the size of the ammeter and related peripheral component parts as well, and a U-shaped bypass linkage mechanism was found to allow successful interlocking. However, the increasing number of gears meant a new challenge for the developers to deal with backlashes. Gears fail to move without any play. Play, however, causes backlash. A considerable amount of time was spent on tightening the dimensions and tolerances of gear component parts to the allowable limits and minimizing possible play.

After the successful reduction of backlash in the control section to the possible minimum level, in the final gear engagement section with the shutter unit, careful manual adjustment was carried out for individual cameras. The tactile click touch dial and accurately responding shutter operation may be attributed to the diligent handwork by the workers in the process of fabrication.

The background described above indicates that the FM2 and FE2 look similar in the external view but they are independent of each other and there has been no camera developed uniting the two models. This was a comprehensive compilation of manual SLR cameras, and Nikon took on the challenge of implementing it as the manual camera for the 21st century.

Sophisticated body and refined capabilities

Brass cover formed by drawing

For the FM3A, the external frame parts were also very hard to implement. The body top cover was formed by drawing a solid plate of brass, which could be implemented fortunately based on the know-how. In the typical drawing method, drawn-to-thinner portions are likely to be easily broken. In actuality, brass plate is drawn gradually based on a step-by-step approach rather than by a single action to form the external frame. Also for this drawing process, the advice of elderly experienced engineers was useful. The raw material for the external frame of FM3A is 0.7 mm in thickness, which is drawn to the thinnest portion of only around 0.2 mm.

In those days when metal body cameras were in full flower, it was a common practice that metallic materials were mechanically stamped to form the camera body. However, in recent years, as the molding of plastic materials becomes predominant, the mechanical pressing of metallic materials is a vanishing technology falling into disuse. The engineers who have experienced the age of the traditional technology contributed to the successful implementation of FM3A.

Brilliantly shining details like handicrafts

At first glance, the FM3A looks the same as the FM2, though the pointed section of the pentaprism is designed, taking a cue from the Nikon F, as the starting point of Nikon's SLR cameras. In addition, in contrast to the FM2 which adopted the black shutter dial for the chrome body, the dial was changed to a chrome finish in the FM3A to better fit the chrome body. It was a design of exquisite taste.

In addition, the release button ring and the film windup lever are designed with lathe-turning patterns on the top surface, showing the designer's care with texture. The attention to every detail of the product produced such refinement as that of craftwork. To the camera, functionality is not necessarily everything. It also demonstrates how eager Nikon was to manufacture the camera, as the costs incurred were very high due to the previously unimaginable details.

Supporting the TTL flash control of Speedlight and automatic setting of film sensitivity

The FM3A manufactured as a manual SLR camera in the 21st century has made steady progress also in the details with cutting-edge specifications. One of the enhancements includes TTL flash control of Speedlight, which has been strongly requested by users. In addition, at the base of the mount in the windup side, a flash control button of one negative step is newly installed. This flash control button will be useful as a solution to overexposure in taking portrait photos. Furthermore, the DX contact is installed for automatic setting of film sensitivity, one of the essential elements for the present-day specifications.

On the other hand, some sections are designed with analog technologies. Since the 1990s, when the full proliferation of AF SLR cameras started, electric circuits integrated in cameras have been successively digitized, though the FM3A adopts analog circuits. Besides, the digital signals from film speed dial and DX (film cartridge) are converted into analog signals for determination of exposure levels.

Significantly brightened viewfinder due to the newly adopted focusing screen

One of the important points to remember regarding the features of FM3A is the viewfinder, which is important for manual focus cameras. Taking a look at the design values of finder coverage of 93% and 0.83x magnification (with use of 50 mm standard lens, at infinity (∞)), the viewfinder seems to offer typical performance, though it is found brighter and easier to see when actually viewed compared to the one in the FM2.

In addition, for the manual focusing camera, a special attention has been paid to the focusing screen. It is designed with improved diffusion of transmitted light and also the same technology as adopted in F3 for the central split. The diffusion is increased by the addition of grids onto the smooth split prism surface, thereby eliminating possible blackout even when a slightly darker lens is mounted. Complete blackout of finder image never occurs even when the aperture is stopped down to f/22 and the preview button is pressed. The focusing screen is available in three types, K3 (split-image microprism type) provided as standard, B3 (matte type), and E3 (matte type with horizontal and vertical line etchings).

Unrealized spot metering and mirror-up functions

The functions spot metering and mirror-up have not been realized despite a great deal of effort.

The spot metering takes an exposure reading based on the measurement of light intensity on a limited range of the central part of the frame, and thus it is useful for precise determination of exposure level. The currently available cameras incorporate photocells composed of many separate light-receiving faces, and spot metering is available by using the output obtained from the central part of individual photocells.

However, the photocells (SPD: silicon photo diode) in the FM3A are located in the right and left sides of the eyepiece behind the pentaprism and the light-receiving faces are not separated. In order to make the spot metering practically available, the physical "screens" are required immediately before the photocells to expose only the central part to the light rays. In practice, however, the pentaprism is confined in a limited area and the two photocells are located on the right and left sides. The adoption of spot metering advanced to the trial-manufacturing phase, though it was extremely difficult to ensure that the "screens" for both photocells moved forward and backward accurately as intended in the mass-production phase, and unfortunately the spot metering did not become a reality.

Similarly, the adoption of the mirror-up function was also abandoned, due to the efforts to achieve the hybrid shutter as the heart of the FM3A and due to the concentration of efforts on the implementation of successful interlocking by the control section.

Debut of FM3A and the story of what happened later to the camera

A camera typical of 2001

After about one year of the development phase, volume production of FM3A was launched in April 2000 in Mito Nikon. The interlocking between control section and shutter unit required a great deal of labor. Fine adjustment of individual units was persistently performed on the production line.

After clearing many obstacles, the FM3A reached completion and went on the market in July 2001.

It was a period of transition from film-based camera to digital camera. Making a debut under those conditions, the manual SLR camera had a great impact on the users and received an enthusiastic response. Before the product went on sale, a rush of orders came from the users, and specialized camera magazines published a detailed feature story about FM3A one after another. At the period of sale in 2001, production could not catch up with the demand.

The camera received the 2001 Good Design Award and it was selected as 2001 Japanese Historical Camera (sponsored by the Japan Camera Industry Institute). In addition, it won the Special Prize in the Camera Grand Prix 2002 selected by the Camera Journal Press Club. Remarks on the selection state that FM3A excels in popularity, topicality, and advanced state. Today when the AF, digital and other electronic applications are in full flower, development of the genuine MFSLR (manual SLR) camera is very meaningful. Specifically, the camera was highly evaluated as follows: "It is the genuine MFSLR camera which allows the users to actually feel the pleasure of taking photographs through the operation of camera; it is an easy-to-handle camera also for beginners gaining experience in taking pictures due to the simple manual exposure setting, aperture-priority AE function, and the match-needle, stop-down metering." These remarks just refer to what Nikon intended when it decided to manufacture the camera. In this regard, Nikon earned an excellent reputation as a manufacturer taking on the challenges of answering the needs of Nikon product lovers in a situation in which the competitors were backing away from production of manual focus cameras.

Exposed to a wave of digitization

In the heyday of digitization, the FM3A helped to teach the enjoyment of taking photographs slowly and carefully without haste. However, it could not live long like the previous generation model FM2 that had been a best-seller for 16 years. This was caused by fast progress of digitization that was beyond expectations. In January 2006, five years from its birth, production of FM3A was discontinued. In addition, F100, F80 and other major film-based cameras were also dropped from production in conjunction.

The reduction of the lineup of film-based cameras was necessary, to allow Nikon to concentrate its resources on the digital camera business. Regrettably the FM3A came to an end.

In the production of FM3A, the subcontractors closely associated with Mito Nikon played an important role. They had been involved in the production of FM2 and/or F3, and in the neighborhood of Mito Nikon, production of manual cameras was growing actively as a local industry. This suggests that FM3A may not be realized in any location other than Mito.

However, in the period of transition from manual focus to auto focus and digital control, the engineers competent to fabricate component parts for manual cameras were getting on toward the age of retirement. An engineer from the subcontractor engaged in the production of leather grain for FM3A was also getting close to retirement age. There is a story that he had ideas about retiring from the company, but he was reportedly prevented from leaving the company.

"The timing was really good for the implementation of the project," a staff in charge of design said later. Year 2001 was just the right time for the realization of FM3A.

Emotional attachment of Nikon engineers to FM3A

One day in January 2006, immediately before Nikon formally announced the discontinuance of production of FM3A, an e-mail was received at Nikon from Mito Nikon. The subject stated "Reporting on the last shipment of FM3A." The e-mail message reads: "We would like to inform you that FM3A entered the volume production in April 2001 and its production is discontinued with the last shipment in January 2006. We would like to acknowledge the continued guidance and cooperation."

The staff in charge of design of FM3A is still keeping the e-mail message. The FM3A was a camera to which everyone involved in the production is deeply attached.

Camera Chronicle

Archives of corporate history subject matter related to Nikon cameras, including rare materials, as well as product photos of cameras and lenses.