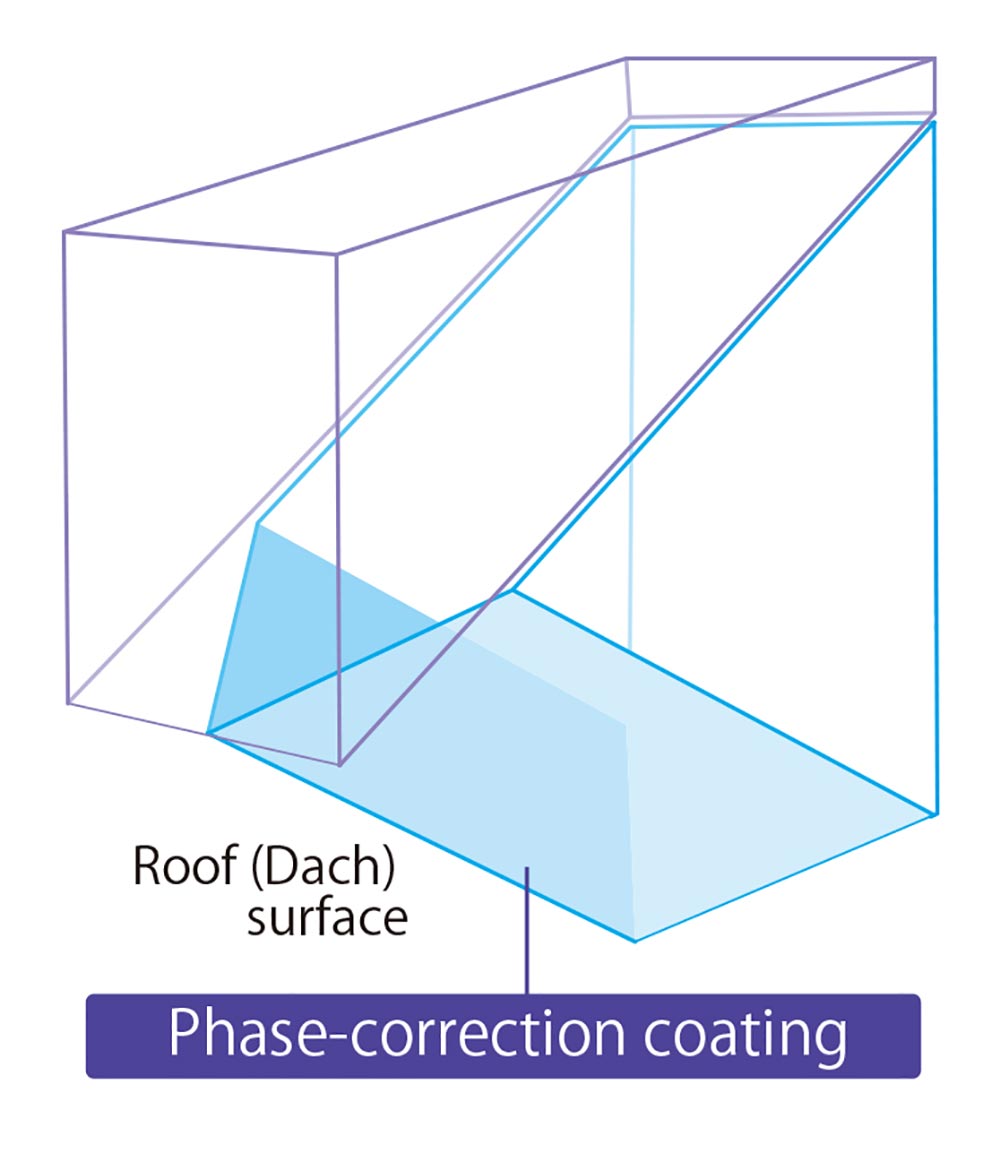

Coating on roof (Dach) prism

Structure and Optical Technologies

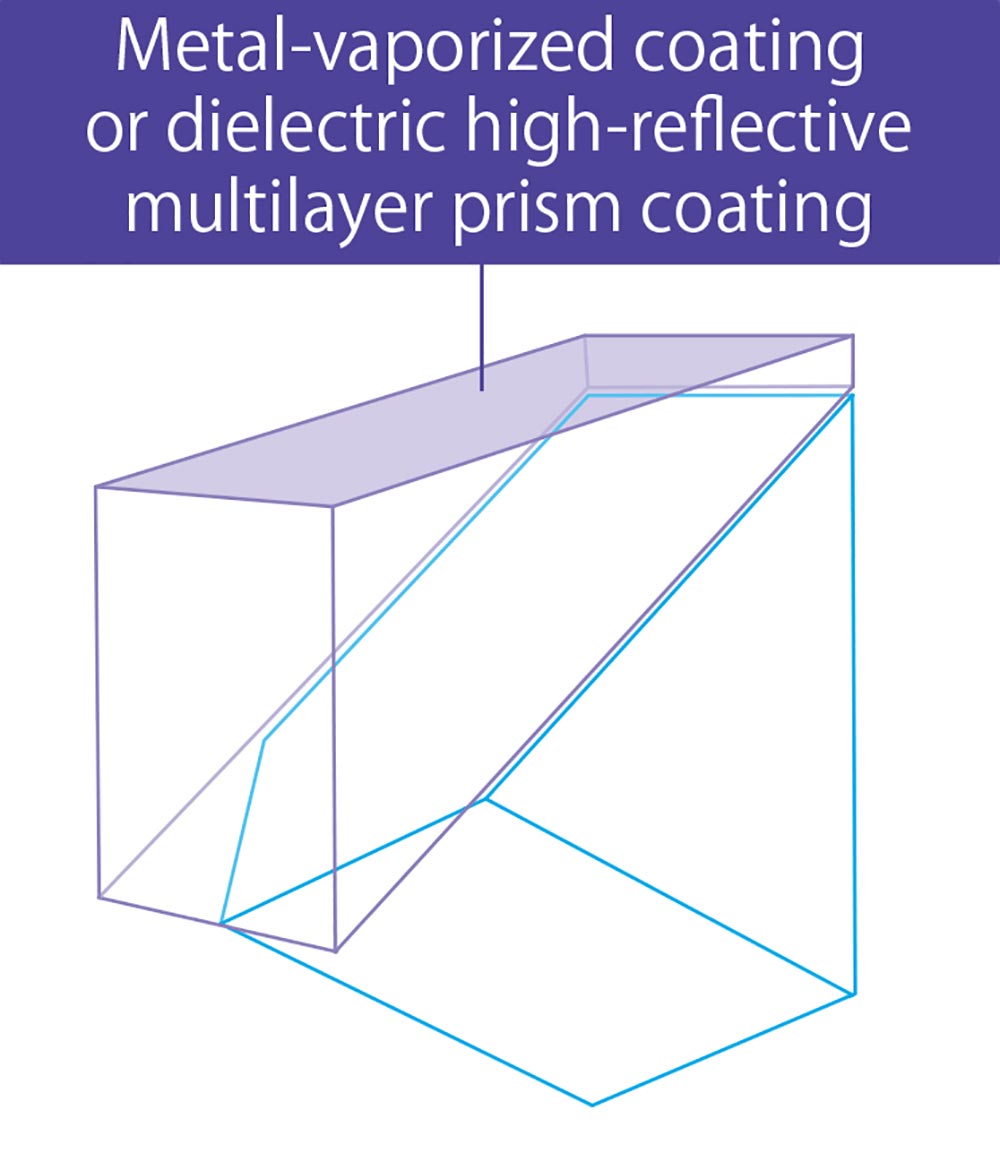

Multilayer coating is also applied to prisms to raise transmittance. A roof prism system has one surface that does not feature total internal reflection, so vapor deposition with metals, etc. must be used to raise the reflectivity of this surface. Also, phasecorrection coating on roof surface ensures high-contrast images.

- *Binoculars' brightness and contrast are affected by not only prism coatings, but also the number of objective lens and eyepiece lens, and types of coatings.

Metal-vaporized, high-reflectivity prism coating

Using vacuum-vaporization technology, metallic material such as aluminum or silver is applied to the reverse side of a prism surface that is not totally reflective. This raises the reflectivity of the prism mirror surface.

Dielectric high-reflective multilayer prism coating

This coating features reflectance that exceeds 99%. By utilizing light interference, this coating assures high reflectivity across the full visible range, and ensures high color reproducibility.

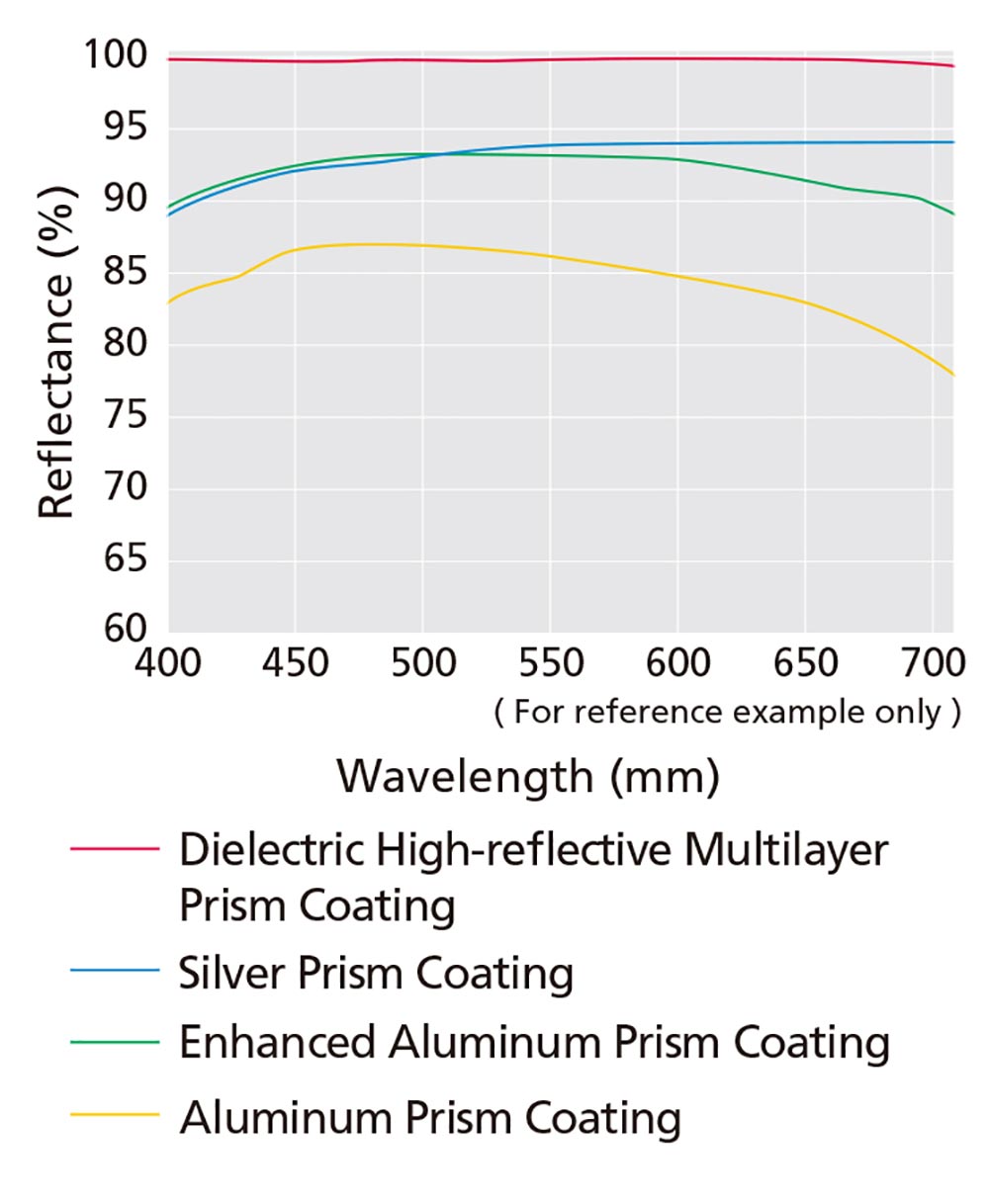

Reflectance characteristics of prism coatings on mirror surface

The horizontal axis indicates the wavelength of light. The vertical axis indicates the reflectance of light.

Binoculars' brightness is determined not only by the reflective mirror, but also by the total optical system such as the number of lenses and quality of coatings.

Phase-correction coating

A roof (Dach) surface can cause phase shift of light that affects image resolution. This phenomenon is caused by phase differences arising from total light reflection on a roof (Dach) surface and it can occur with even a perfectly processed prism. Phase-correction coating is applied to the surface to minimize loss of resolution, ensuring high-contrast images.