Nikon SP Limited Edition

- Nikon SP Limited Edition realizes the impossible

- Birth of the SP Reproduction Project

- Reproduction of Universal Viewfinder

- Procurement of equipment and materials attained by drawing on the experience gained in the reproduction of the S3

- Assembly through Completion

- Major Specifications

- Differences between the SP Limited Edition and the original SP

Nikon SP Limited Edition realizes the impossible

Nikon SP Limited Edition (hereinafter referred to as SP repro model) is a reproduction model of Nikon SP, the most sophisticated coupled rangefinder camera of its time released in 1957. It is the second limited edition of the Nikon S series, following the Nikon S3 Year 2000 Millennium Model released in 2000 to commemorate the year 2000 millennium.

Nikon SP is a legendary well-designed camera which enjoyed a great popularity, especially among press photographers and professional photographers, because of its high precision, smooth handling, high endurance, and elaborate workmanship. After the introduction of the S3 replica model, there was a growing call for the revival of SP from many Nikon product lovers.

The SP, developed to directly compete with the great rangefinder camera Leica M3, had the outstanding selling point of a universal viewfinder, which allowed selecting the field frame appropriate for the focal length of the lens mounted. The universal viewfinder could accommodate a total of six (6) focal lengths, 2.8 cm, 3.5 cm, 5 cm, 8.5 cm, 10.5 cm, and 13.5 cm, thereby providing the largest number of frame options in the world at that time, and it was the only one model among the S series rangefinder cameras to incorporate the automated parallax compensation. The viewfinder is also known as “couple finders” due to the two viewing windows arranged side-by-side, one for wide-angle lenses and the other for standard to medium telephoto lenses. The viewfinder featured such a complicated and elaborate design incorporating a total of 28 lens elements that it was said to be impossible to reproduce it with the current techniques, but it was recreated with all the know-how about the manufacturing practices of mechanical cameras. The SP repro model was made as identical as possible to the original Nikon SP.

Realizing the reproduction of SP was of great significance for the transmission of manufacturing techniques of mechanical cameras. The SP repro model was produced in limited quantities of 2,500 units and distributed only in Japan. The orders were accepted from January 14, 2005 to June 30, 2005, and it was first handed over to the customers on March 18, 2005 at camera shops across the country. The standard equipment lens was a reproduction of the W-Nikkor 3.5 cm f/1.8 lens. It was a multi-coated lens just like the currently available Nikkor lenses to ensure a higher degree of optical performance.

The camera body and lens were both inscribed with serial numbers from 0001 to 2500, and the camera body and lens are sold in pairs with the same serial numbers. Each set of body and lens was provided with the serial number certificate. The pair of product number one (camera body: SP0001 and lens: 0001) was donated to the JCII Camera Museum in Chiyoda-ku, Tokyo.

Product name: Nikon SP Limited Edition

with W-Nikkor 3.5 cm f/1.8, Serial Number Certificate, lens cap, lens hood, and camera case

Suggested retail price: 690,000 yen (724,500 yen including tax)

Order accepting period: January 14, 2005 to June 30, 2005

Start of sales: March 18, 2005; handed over to the customers at the shop counter

Number of units produced: 2,500

Birth of the SP Reproduction Project

Thirst for more sophisticated manufacturing

In the revival of S3, Mito Nikon demonstrated its technical expertise, though the company engineers were not fully satisfied with the successful results because of their desire for more sophisticated manufacturing. Their thirst for a higher level of manufacturing was targeted at Nikon SP, the top of the line rangefinder cameras in those days.

The engineers intended to take on the challenge of reproducing the complicated and elaborate universal viewfinder which they had once given up in the early stage of S series classical camera reproduction project in 1998 by saying “Honestly, we cannot make a reproduction.” Indeed, even for the S3, they had a long and extremely tough road to the successful reproduction of the sophisticated mechanism and smart appearance.

However, picking up the S3 as the first target for reproduction and the eventual success made the engineers feel confident that they would be able to reproduce the universal viewfinder. The engineers in Mito Nikon had come to have a strong feeling that they could take on the challenge. In addition, the S3 replica model was much more favorably received than expected and this also supported the Mito Nikon engineers in taking on the challenge.

Project on the move behind the scenes one year after the successful reproduction of S3

According to the records maintained at Mito Nikon, in July 2001, one year after start of shipment of the S3 replica model, the collection of the SP data was initiated. In the following August, two SP bodies were purchased from a pre-owned camera shop at Ginza, Tokyo. Furthermore, drawings were obtained from Nikon. Thus, the SP reproduction project including inspecting the viewfinder got started behind the scenes, though the formal project team was not yet formed.

Subsequently, the Nikon SP reproduction project was formally approved by Nikon in September 2002 and given the go-ahead. As in the case of the reproduction of S3, Mito Nikon was responsible for manufacturing the body, while Tochigi Nikon took charge of manufacturing the W-Nikkor 3.5 cm f/1.8 lens and the viewfinder optical system lens and prism which were to be released in combination with the body. Nikon Photo Products Inc. (present Nikon Imaging Japan Inc.)worked for marketing, officially launching the project.

Reproduction of Universal Viewfinder

Unknown method for viewfinder assembly

In February 2003, trial manufacturing of the SP body was started at Mito Nikon in response to the go-ahead given by Nikon. In actuality, however, the project had already proceeded for about two years behind the scenes. The focus of the project was on the most difficult challenge of reproducing the universal viewfinder.

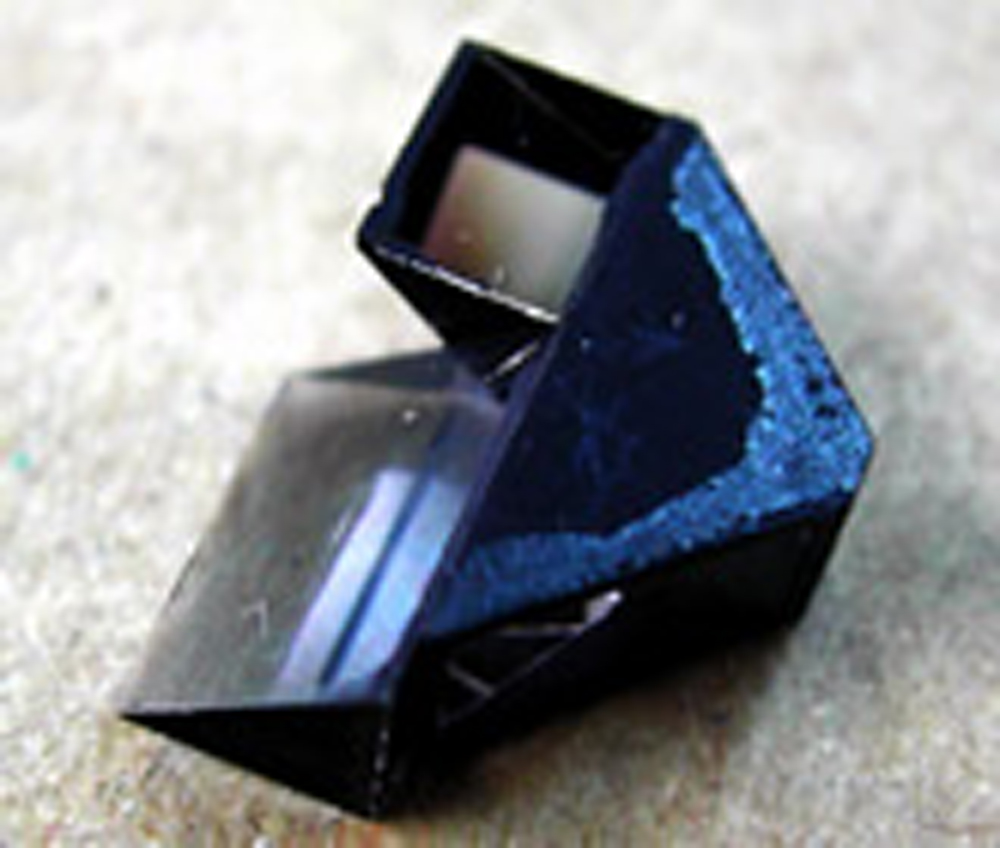

One of the significant differences between SP and S3 was the number of component parts. The total number of component parts was 895 for SP, compared to 816 for S3. For the lens and prism comprising the viewfinder, SP incorporated as many as 28 parts compared to 13 in S3, demonstrating that the SP had a very complicated construction.

The viewfinder of SP had been considered impossible to reproduce with the current manufacturing practices. However, Mito Nikon dismantled the SP purchased from the secondhand camera shop to carefully examine individual component parts and understand the construction of the viewfinder, and it reached to the projection that the viewfinder could be reproduced with the current techniques. Furthermore, due to the technical capabilities evidenced by the successful reproduction of S3, the eagerness for the revival of SP was increasingly enhanced. In practice, however, the engineers could not determine how the complicated viewfinder was fabricated in the days of the original SP.

The viewfinder of the SP features so-called couple finders having two viewing windows arranged side-by-side on the right and left. This allows selecting the appropriate field frame to match the lens mounted, wide-angle lenses in the left for focal lengths of 2.8 cm and 3.5 cm and standard to medium telephoto lenses in the right for focal lengths of 5 cm, 8.5 cm, 10.5 cm, and 13.5 cm. Field frame selection is available with the viewfinder selector installed to rotate around the rewind crank.

In addition to the difficult reproduction of the viewfinder mechanism, there was another difficulty: the method to increase the accuracy of the viewfinder was not discovered right away. However, the accuracy of the SP viewfinder is the biggest feature of the SP. The engineers were reportedly struggling to find the solutions for a half year while examining the viewfinder.

The viewfinder was assembled basically in accordance with the charts remaining in the drawings, though there was no clue regarding the assembly procedure. The engineers could not find any approach to define a position as a reference simply by looking at the drawings. In addition, even though they dismantled the purchased pre-owned SPs for reverse engineering, this could not help the engineers to define the references due to the individual differences between the used cameras.

Engineers used to take charge of adjustment at their own discretion

It is not known how the cameras were fabricated and the accuracy was insured in the days of the original SP, when there were none of the lasers and other equipment for adjustment and testing and inspection of optical systems that are available today. When the engineers were trying to fabricate the viewfinder, they found that no document existed referring to the tools and materials used in those days. It was believed that, back then, the manufacturing staff might originally prepare the required tools. Moreover, individual engineers would have also made adjustment of the viewfinder separately. Based on the fact that a total of 23,000 units of SP, later appraised as an excellent machine, were shipped even under such circumstances, clearly the technical expertise of that time in the manufacturing division must have been outstanding. Every stage of the reproduction project pointed to the signs of the greatness of the technical skills in those days.

Mito Nikon eventually fabricated and installed an original system for the adjustment of the optical axis using a collimator and laser, and improved the accuracy of adjustment and also saved man-hours. Even so, individual tasks involved manual detailed operations, and it still took a great deal of time to assemble and adjust the viewfinder.

Ghost caused by high optical performance

Looking into the viewfinder of the SP repro model, we find that the subjects look brighter and clearer than through the original SP. This can be partly attributed to the deteriorated visual performance of viewfinder on the original SP due to secular changes, though the reproduction model takes full advantage of the significantly enhanced performance of prisms and lens elements incorporated in the viewfinder, compared to the original model. The viewfinder on the repro model is superior to the original in visual performance and visibility.

However, surprisingly, there was a hidden trap caused by the enhanced optical performance. Light rays can pass through the viewfinder more smoothly and this causes the unexpected generation of ghost flare in the visual field of the viewfinder. Even any slight misalignment between prisms incorporated can be reflected as ghost flare.

For the ghost, a solution was established after much trial and error through fine position alignment between prisms by manually trimming some prisms constituting the viewfinder. The trimming involved hard work to achieve prism adjustments in the order of only 0.2 mm. Any excess trimming would deteriorate the principal optical performance. The solution was reinforced by coating the prism corners with black ink using a brush to block any detrimental stray light due to light reflection. This demonstrates the high level of technique achieved by elaborate hand work.

In addition, it took much time until the colors of the field frame in the viewfinder were determined. The couple finders were reproduced with the right-side frame colored in white for focal lengths of 5 cm to 8.5 cm, yellow for 10.5 cm and red for 13.5 cm. However, when examining an existing original SP, the frame colors are found changed due to aging and the original colors cannot be identified. The frame colors cannot be represented in any simple colors, and the trial and error method was used by mixing various colors. This shows how the engineers were stuck at such details because they aimed to achieve a faithful reproduction to the original.

Procurement of equipment and materials attained by drawing on the experience gained in the reproduction of the S3

Serial numbers from 0001 through 2500 without any omission

Based on the experience gained in the reproduction of the S3, the procurement of component parts other than the viewfinder was started in due course. Again in this project, cooperation was received from the subcontractor companies that helped Nikon in the S3 reproduction project. The SP repro model was developed with the in-house identification code of M400. The experienced engineers in the subcontractor companies should have noticed to a certain extent what the code meant.

The trend of the present times is increasingly moving toward digitalization. Nikon has also been devoting its main efforts to the development of a digital SLR. Possibly, this project would be the last attempt to reproduce any classic camera; this was the feeling of not only Mito Nikon but also of the subcontractor companies that had been supporting Nikon for a long period of time.

For the etching of the serial numbers on the upper cover, which had been one of the difficult problems to deal with in the S3 reproduction project, the shipped SP was marked with serial numbers from 0001 through 2500 without any omission. Certainly, individual engineers enhanced their skill levels through their experience with the reproduction of the S3 replica model. Even so, it was a tough task to finish both the body and the lens up to the serial number 2,500 without any omission. We can imagine how necessary it was for all the parties involved, including Tochigi Nikon that took charge of the lens, to pay special attention to details in doing the jobs.

In particular, as the unit with serial number 0001 was going to be donated to the JCII Camera Museum, great care was exercised in fabricating the No. 0001 unit by preparing five (5) units for fabrication just to be sure, and the best one of them was shipped. In this regard, it was reported that only two of the five units were successfully completed, which shows that volume reproduction of vintage cameras is still difficult.

Assembly included self-timer

A big problem arose. The subcontractor company that manufactured the self-timers for the S3 replica model rejected the manufacturing of the self-timer as stating, “We cannot afford to manufacture the self-timers.” The domestic self-timer workshops had been closed. The S3 and SP incorporate the same type of mechanical self-timer. The self-timer features a complicated mechanism configured with a total of 58 component parts. In practice, it was not acceptable that only the self-timer would be different from that used in the original, therefore, there was no other choice for Mito Nikon but to fabricate the self-timer on its own.

Mito Nikon asked the subcontractor company to provide the drawings for the self-timer. Fortunately, the subcontractor company responded to the request by voluntarily transferring the drawings and special tools free of charge to Nikon. Moreover, the subcontractor introduced all the affiliates involved in the production of the self-timer to Nikon. It was an exceptional case that a manufacturer transferred all the know-how about a certain product at no charge. This was the result of a close rapport between engineers who could understand the significance of the project of reproducing the time-proven camera and the importance of transmitting the technical expertise.

The Mito Nikon staff in charge of the negotiations expressed their deep gratitude. When the drawings for the self-timer were transferred, the staff was suggested that it would cost a lot of money even if the self-timer could be reproduced. However, using creative devices, the self-timer was successfully reproduced as close as possible to the original at lower cost.

The mechanical self-timer generates a humming sound while in operation. Special attention was also paid to the operating sound and as a result, a close-to-the-original humming sound was achieved owing to the fine adjustment.

Assembly through Completion

Ten times more assembly time compared to FM3A

In July 2003, about one year after the project was formally launched, volume production was started at Mito Nikon when they were confident that they could successfully procure component parts and apply assembly methods.

Adjacent to the production line of the SP repro model installed in the plant, the production of FM3A was also underway. As in the production of the S3 replica model, the production line was free of any belt conveyors, and the worker involved in a process completed the assigned task and then handed the products over to the next worker in the subsequent process.

In the early stage of production, 13 units were produced daily with a total of 20 staff members. Due to the experience in the reproduction of the S3, the workers had become more skilled in the assigned work, though it was found that total man-hours increased by around 30%, including the labor required for the viewfinder, compared to the production of S3. In addition, the viewfinder assembly required 50% more labor and time than the S3, thereby taking 10 times more time for assembly compared to the FM3A manufactured simultaneously in the neighboring line.

Especially when working with the viewfinder, the workers had a tough time protecting it against dust and particles. Once dust and particles enter the camera interior, they can be seen enlarged within the viewfinder. The individual manufacturing steps were reviewed and special attention was paid to protect the inside of the camera body against the possible generation of dust and particles, or arrangements were made to devise a proper method of removing any dust and particles. For example, a steady and persistent effort was spent to hold the component parts or the work in process in a covered container to transfer in the line, putting the lid on the container immediately after completion of assembly.

The happiness to feel its roots of the Nikon camera

In March 2004, the SP was first shipped from Mito Nikon. In the camera market, digital cameras had assumed a dominant position, and the number of units produced was finally set at 2,500. Orders were taken starting in January 2005. Shipment of SP repro model was started in March 2005, immediately after the introduction of Nikon’s flagship of both film and digital cameras, Nikon F6 (December 2004) and Nikon D2X (February 2005). Thus the Nikon S model reproduction project, which Mito Nikon had been challenging up to the very limit of the technology, came to an end.

The SP repro model was realized based on the engineers’ eagerness to make things using skilled, hands-on human labor. All the persons involved were confident that they had created an object surpassing the original. This camera is close to the hearts of its creators.

A worker in Mito Nikon who was involved in the manufacturing gave his impressions of the project after completion stating, “I am very happy to feel its roots of Nikon cameras. We have faced an impossible challenge. It has been a soul-rattling project for all of us engineers involved.” He added, “You can understand its value when you use it.” These words speak for everything relating to the project.

Major Specifications

Nikon SP Limited Edition

| Camera type | 35 mm coupled rangefinder focal-plane shutter camera |

|---|---|

| Film format | 35 mm |

| Picture size | 24 mm × 36 mm |

| Lens mount | Nikon S mount (Bayonet mount) |

| Shutter | Horizontal-traveling rubberized silk cloth focal-plane shutter |

| Shutter speeds | T, B, 1, 1/2, 1/4, 1/8, 1/15, 1/30, 1/60, 1/125, 1/250, 1/500, 1/1000 sec. graduated at regular intervals |

| Focusing scales | Marked in meters (∞ to 0.9) |

| Self-timer | Variable duration type (with 3, 6, and 10 sec. marks) |

| Flash sync. contact | Variable according to time, with sync. socket, Speedlight unit synchronized at 1/60 sec. or less |

| Finder (with field frame) | Bright frame type life-size viewfinder, 5 cm, 8.5 cm, 10.5 cm, 13.5 cm with light figure frame; Albada type wide-angle viewfinder, 2.8 cm, 3.5 cm |

| Film sensitivity | Marked in ISO sensitivity |

| Film advance | One action lever, 136-degree rotation, Available inch-by-inch film advance, Preparatory film feeding angle 15 degrees |

| Film rewind | Crank |

| Frame counter | Automatic reset and additive type |

| Camera back | Removable design (Not compatible with motor drive) |

| Body dimensions (Approx.) | 136 mm (width) × 81 mm (height) × 43 mm (depth) |

| Weight (Approx.) | 590 g (body), 750 g (with W-Nikkor 3.5 cm F1.8) |

| Price (with sales tax) | 724,500 yen (with W-Nikkor 3.5 cm f/1.8, Serial Number Certificate, lens cap, lens hood, and camera case) |

W-Nikkor 3.5 cm F1.8

| Lens configuration | 7 elements in 5 groups |

|---|---|

| Focal length | 3.5 cm |

| F-number | f/1.8 |

| Aperture scales | f/1.8 to f/22 |

| Focusing scales | 0.9 m to ∞ |

| Angle of view | 62° diagonal |

| Shortest object distance | 0.9 m |

| Attachment size | 43 mm (P=0.75 mm) for the filter mounting, 48 mm (P=0.5 mm) for the hood cap installation |

| Hood | 48 mm; Spring-loaded type |

| Cap | 48 mm (P=0.5 mm); Spring-loaded type |

| Dimensions | 59.0 mm (Diameter; including lens removing tab) × 22.5 mm (Length; measured from the tip of lens to the bayonet reference surface) |

| Weight (Approx.) | 160 g (without accessories) |

Differences between the SP Limited Edition and the original SP

- Focusing scales:

- Unified to the unit of meters (m) from the original range ring marked in two units, m and ft

- Automated frame counter dial:

- Changed to "24" from "20"

- Film sensitivity dial:

- Changed to ISO from ASA

- Strap lugs:

- Materials were changed to stainless steel from brass, and to chrome finish from nickel-chrome finish.

- Film rewind crank:

- Slightly changed external design

- Film rewind knob:

- Slightly changed external design

- Camera back pressure plate:

- Slightly changed external design

- Accessory shoe:

- Slightly changed external design

- Shutter dial sync. indicator color:

- Slightly changed

- Body number:

- "SP" inscribed before the serial number

- Lens:

- "Nikon" and "MADE IN JAPAN" inscribed, and multi-coating

- Lens cap:

- Changed to aluminum from plastic ("Nikon" on the back surface)

- Lens hood:

- "Nikon" inscribed

Camera Chronicle

Archives of corporate history subject matter related to Nikon cameras, including rare materials, as well as product photos of cameras and lenses.